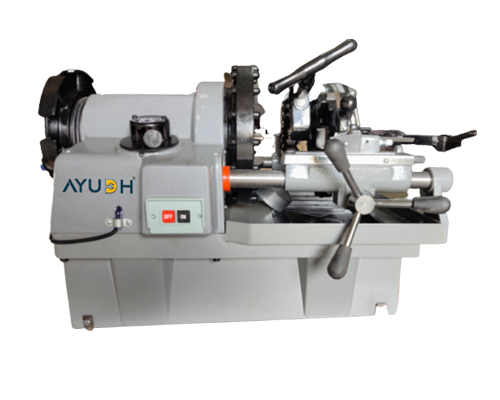

Ayudh GM2520 Pipe Grooving

Pipe Grooving Machine Work:

Pipe grooving machines utilize different techniques to create grooves, depending on the machine type. The most common methods include roll grooving, press grooving, and cut grooving.

- Roll Grooving: This method involves passing the pipe through grooving rolls, which form the grooves gradually as the pipe moves forward. Roll grooving is suitable for various pipe materials, including steel, copper, and PVC.

- Press Grooving: In press grooving, the machine utilizes hydraulic or mechanical force to press grooves into the pipe’s surface. This method is often quicker and ideal for larger pipes and thicker materials.

- Cut Grooving: Cut grooving involves cutting precise grooves into the pipe using specialized cutting wheels. This method is popular for pipes with thick walls and limited space for grooving.

Machine Specification:

| Product Code | AYUDH GM2520 | |

| Pipe Capacity | : | 1″-8″(25 mm to 200mm) |

| Power | : | 750 W Induction, 220 V 50/60 HZ |

| Spindle Speed | : | 26 RPM |

| Weight | : | 99 Kg |

| Package Size | : | 690 x 390x 710(mm) |

| Working Capacity | : | 1″-8″ Sch10~Sch40 Seamless / Galvanized Pipe |

| Standard Accessories | : | Upper rollers, shaft and lower rollers start from 1-8″ |

| Pipe Support Stand, Tools with Footswitch | ||

| Instruction Manual |

Related Tag: Pipe grooving machine dealers, pipe grooving machines manufacturer, grooving machines pipe grooving machine price