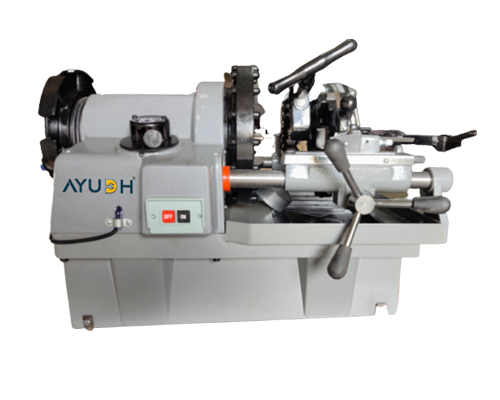

Pipe Grooving Machines

A pipe grooving machine is a specialized tool used to create grooves on the ends of pipes. These grooves facilitate easy and secure pipe joining without the need for welding or threading. The grooves made by the machine allow the pipes to interlock, creating a strong and leak-resistant connection.

Types of pipe grooving machines

Pipe grooving machines utilize different techniques to create grooves, depending on the machine type. The most common methods include roll grooving, press grooving, and cut grooving.

- Roll Grooving

- Press Grooving

- Cut Grooving

Pipe grooving machines offer numerous benefits that make them preferable over traditional pipe joining methods

Machine Specification:

| Product Code | AYUDH GM5030A | |

| Pipe Capacity | : | 2″-12″(50 mm to 300 mm) |

| Power | : | 1100 W Induction, 220 V 50/60 HZ |

| Spindle Speed | : | 24 RPM |

| Weight | : | 143 Kg |

| Package Size | : | 805 x 425 x 890 (mm) |

| Working Capacity | : | 2″-12″ Sch 10 Steel, Stainless steel |

| 2″-8″ Sch 10/40 Steel, Stainless steel | ||

| Standard Accessories | : | Upper rollers, shaft and lower rollers start from 2-12″ |

| Pipe Support Stand, Tools. | ||

| Instruction Manual |

Related Tag: grooving machine, pipe grooving machine, pipe grooving, ms pipe grooving machine, gi pipe grooving machine, wall grooving machine, pipe grooving machine chennai, pipe cutting grooving machine, electric pipe grooving machine