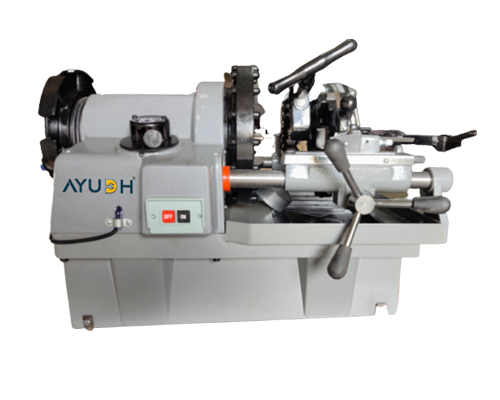

Ayudh GM5030C Pipe Grooving

Types of Pipe Grooving Machines

There are several types of pipe grooving machines, each catering to different pipe dimensions and materials:

Roll Grooving Machines

Roll grooving machines use grooving rolls to gradually shape the grooves on the pipe’s surface. They are suitable for pipes with diameters ranging from 1″ to 24″ and are commonly used for steel and copper pipes.

Press Grooving Machines

Press grooving machines utilize hydraulic or mechanical force to press grooves onto the pipe. These machines are suitable for larger pipes and thicker materials, typically ranging from 2″ to 60″ in diameter.

Cut Grooving Machines

Cut grooving machines employ cutting wheels to make precise grooves on pipes with thick walls. They are commonly used for pipes with diameters above 12″.

Machine Specification

| Product Code | AYUDH GM5030C | |

| Pipe Capacity | : | 2″-12″(50 mm-300 mm) |

| Power | : | 750 W Induction, 220 V 50/60 HZ |

| Spindle Speed | : | 23 RPM |

| Weight | : | 150 Kg |

| Package Size | : | 800 x 760 x 930(mm) |

| Working Capacity | : | 2″-12″ Sch 10 Steel, Stainless steel |

| 2″-8″ Sch 10/40 Steel, Stainless steel | ||

| Standard Accessories | : | Upper rollers, shaft and lower rollers start from 2-12″ |

| Pipe Support Stand, Tools. | ||

| Instruction Manual |

Related Tags: Pipe Grooving Machines, MS Pipe Grooving Machine, Grooving Machine Dealers, Pipe Grooving Machine Chennai, pipe grooving machine price