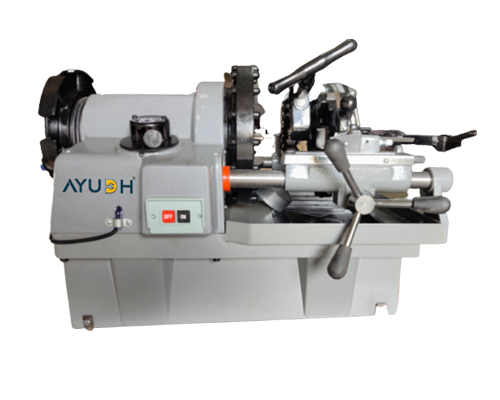

Pipe Threading Supertronic 4SE

Maximizing Efficiency with the Electric Pipe Threading Machine

Workload and Capacity

Consider the volume of pipes you’ll be threading regularly. Choose a machine that can handle your workload without straining its capacity.

Pipe Material and Size

Different pipe materials may require specific threading approaches. Ensure the machine you choose is compatible with the materials you work with, and can handle a range of pipe sizes.

Automation Level

Evaluate how much automation you require. Electric and hydraulic machines offer higher levels of automation compared to manual ones.

Durability and Maintenance

Invest in a machine that’s built to last. Check the machine’s construction materials and read reviews regarding its durability. Additionally, consider maintenance requirements and costs.

Step-by-Step Guide to Using a Electric Pipe Threading Machine

- Prepare the Machine: Set up the machine according to the manufacturer‘s instructions. Ensure it’s securely anchored.

- Select the Die: Choose the appropriate die size for the pipe you’re working with.

- Secure the Pipe: Place the pipe in the machine’s clamps, ensuring it’s held securely.

- Adjust the Depth: Set the threading depth according to your needs.

- Start Threading: Activate the machine and guide the pipe into the die. The machine will thread the pipe automatically.

- Inspect the Thread: Once the threading is complete, inspect the thread for accuracy.

Operations with the Electric Pipe Threading Machine

The Electric Pipe Threading Machine stands tall as a beacon of innovation and efficiency. Its cutting-edge technology, precision threading capabilities, and durability make it a cornerstone of modern industrial operations.

Machine Specification :