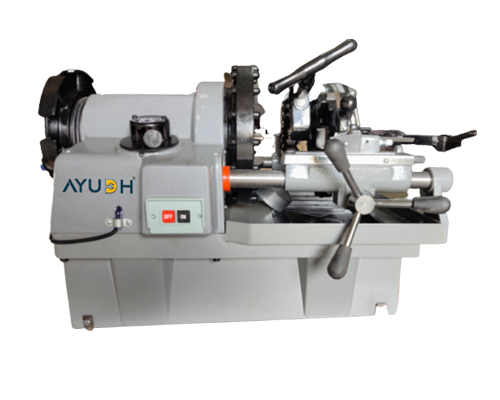

AYUDH 50 Pipe Threading Machine

Ayudh 50 pipe threading machine

It is a specialized tool designed to cut precise threads on the ends of pipes. It is commonly used in various industries and applications where pipes need to be joined together securely and create leak-free connections.

The primary purpose of a pipe threading machine is to facilitate the threading process, which involves cutting spiral grooves along the outer or inner surface of a pipe. These grooves, known as threads, allow for the attachment of fittings, connectors, or other pipes, enabling the creation of a secure and tight connection.

Pipe threading machines come in different sizes and configurations to accommodate various pipe diameters and threading requirements. They are equipped with a die head and a set of dies, which are responsible for cutting the threads on the pipe. The die head is securely mounted on the machine, and the pipe is fed into the machine’s chuck.

Machine Specification

| Product Code | AYUDH 50 |

| Pipe capacity | 1/2″-2″ |

| Power | 1150W-220V,50/60HZ |

| Spindle Speed | 40rpm/min(no load) |

| Weight | 67kgs |

| Package size | 780x550x550(MM) |

| Standard Accessories | Die Head 1/2″-2″ – 1 no |

| Dies BSPT(HS) 1/2″-3/4″ -1 set | |

| Dies BSPT(HS) 1″-2″ -1 set | |

| Tools And Supporting Legs | |

| Optional Accessories | Dies BSPT (HSS) – 1/2″-3/4″ |

| Dies BSPT (HSS) – 1″-2″ |

Related Tag:- Automatic Pipe Threading Machine, Bolt Threading Machine, Electric Threading Machine, bolt and pipe threading machine, pipe and bolt threading machine