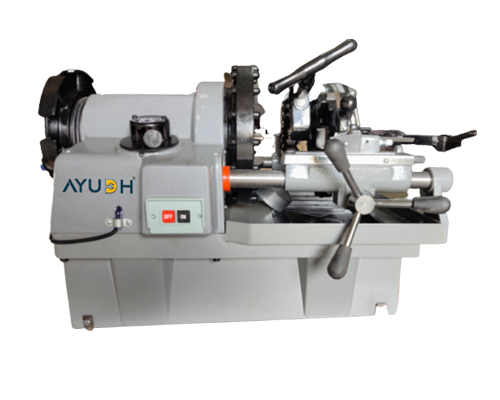

Ayudh GM 2530A

Pipe grooving machines play a pivotal role in industrial applications, facilitating secure and efficient pipe joining without the need for welding or threading. Here’s how they are utilized in various industries:

- Plumbing and HVAC Systems

- Fire Protection Systems

- Oil and Gas Industry

- Water Treatment Plants

- Mining and Construction

- Agriculture and Irrigation

How Pipe Grooving Machines Work

Pipe grooving machines employ various techniques to create grooves on pipes. The most common methods include roll grooving, press grooving, and cut grooving.

Pipe grooving machines have revolutionized the way pipes are joined in industrial applications. Their time-saving attributes, leak resistance, and versatility make them valuable assets in various industries, from plumbing and construction to power generation and pharmaceuticals. As technology continues to evolve, pipe-grooving machines are poised to play an increasingly crucial role in enhancing efficiency and safety in industrial processes.

Machine Specification

| Product Code | AYUDH GM 2530A | |

| Pipe Capacity | : | 1″-12″(25 mm to 300 mm) |

| Power | : | 1100W Induction, 220 V 50/60HZ |

| Spindle Speed | : | 24 RPM |

| Weight | : | 140 Kg |

| Package Size | : | 805 x 425 x 890 (mm) |

| Working Capacity | : | 1″-12″ Sch 10 Steel, Stainless steel |

| 1″-8″ Sch 10/40 Steel, Stainless steel | ||

| Standard Accessories | : | Upper rollers, shaft and lower rollers start from 1-12″ |

| Pipe Support Stand, Tools. | ||

| Instruction Manual |

Related Tag: Pipe Grooving machine dealer, Portable Pipe grooving machines, MS Pipe Grooving Machine Price