Heavy Duty Pipe Threading Machine More Compact For Construction Industries

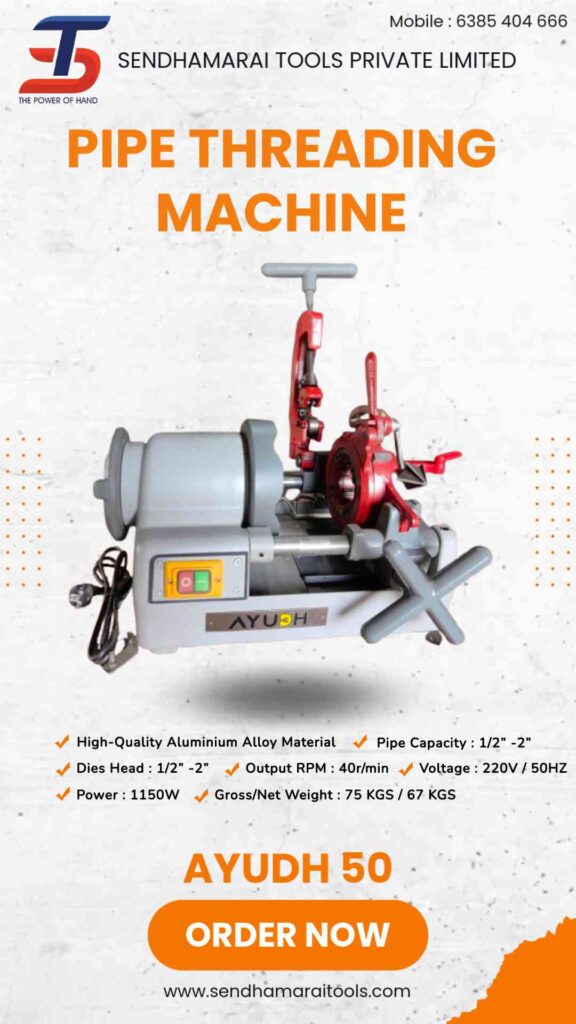

In modern industrial piping systems, the Pipe Threading Machine plays an indispensable role in ensuring leak-proof, durable, and standardised connections. For professionals and industries looking for a dependable and robust threading solution, a machine that threads 1/2″ to 2″ pipes with 40 RPM motor speed and weighs approximately 67 Kgs delivers power, efficiency, and reliability.

Overview of the 1/2 to 2 Inch Pipe Threading Machine

This threading machine is designed to handle a wide range of applications including plumbing, fabrication, HVAC, and gas line installations. Its ability to work with various pipe sizes makes it a universal solution for both commercial and industrial uses.

Key Specifications:

- Pipe Capacity: 1/2 inch to 2 inches

- Motor Speed: 40 RPM

- Machine Weight: 67 Kgs (Approx.)

- Threading Type: BSPT/NPT (customizable)

- Threading Dies: High-speed steel, long-lasting

- Construction: Heavy-duty cast iron base with anti-vibration frame

Advantages of a 40 RPM Motor Speed

The 40 RPM motor speed is optimized for threading steel, galvanized iron, stainless steel, and medium carbon steel pipes. This medium speed provides:

- Enhanced control over thread depth and cut

- Minimized wear on threading dies

- Improved consistency and thread finish

- Reduced chances of pipe slippage or over-threading

Heavy-Duty Pipe Threading Machine Build for Longevity

At 67 kilograms, the machine provides excellent ground stability during operation. The rugged iron frame ensures it withstands job site challenges without any compromise on performance. The vibration damping system embedded into the frame ensures smooth operation, reducing operator fatigue.

Pipe Compatibility and Threading Range

One of the most significant strengths of this threading machine is its compatibility with:

- GI (Galvanized Iron) pipes

- Mild Steel pipes

- Stainless Steel pipes

- PVC-coated conduit pipes

- Black iron pipes

Its universal pipe threading Machine dies allow for threading BSPT and NPT standards, ensuring compliance with international piping norms.

Pipe Threading machine Maintenance and Serviceability

Regular oiling and timely die replacement ensure years of smooth operation. The motor unit and gearbox are built for easy access and minimal maintenance downtime. Spare parts availability is never a concern due to its standardized design.

A Pipe Threading Machine (1/2″–2″) with 40 RPM speed and 67 kg weight is a serious tool for serious professionals. Whether you’re in construction, gas pipelines, or plumbing, this equipment provides consistent performance, safety, and long-term value. Its ability to handle various pipe materials and produce clean, accurate threads makes it an industry essential.

If you’re looking to upgrade your workshop or streamline on-site jobs, investing in this model is a decision that pays off in efficiency, safety, and thread quality.